Step-by-step installation of a solar inverter

Installing a solar inverter step by step

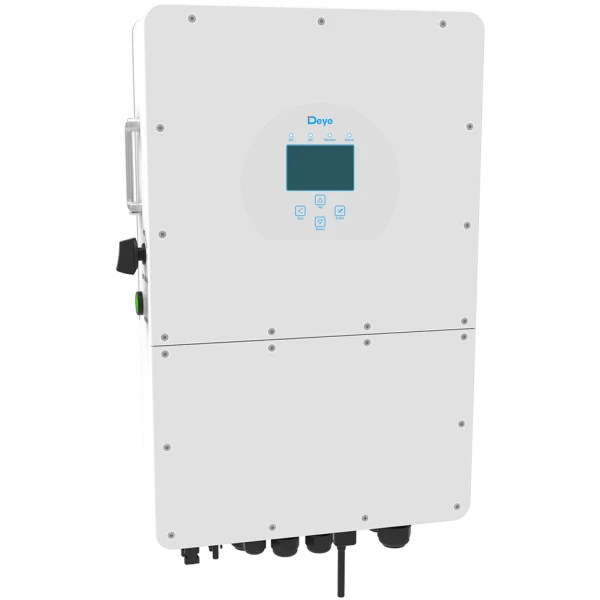

Installing a solar inverter is one of the most important steps in setting up a solar power system, as this device converts the direct current generated by the solar panels into alternating current that can be used by household appliances without any problems. Proper installation determines not only efficiency but also safety, so it is essential to familiarize yourself with the necessary preparations, tools, and protective elements. In this article, we will take a detailed look at the role of the inverter in a solar panel, what to look out for during preparation, how to choose the right type and size of inverter, and then we will present step-by-step instructions for DC and AC side connection, grounding, communication cables, and monitoring system integration. In addition, we will discuss the most common connection errors, testing, maintenance considerations, and when it is necessary to involve a professional to ensure safe and reliable commissioning.

What is a solar inverter and why is it important to install it correctly?

What does an inverter mean in relation to solar panels?

The inverter is one of the most important components of a solar system. This device converts the direct current (DC) generated by the solar panels into alternating current (AC), which is required by household appliances and the public grid.

A solar panel system only generates direct current; if it is not converted, it cannot be used to operate household appliances or machines, nor can it be fed back into the public grid.

In addition, the inverter does more than that: modern devices often have integrated optimization and protection functions (such as overvoltage protection and grid control), and even monitoring, so you can track how much energy your system is generating.

In short, without an inverter, a solar system would not function properly, so it is very important to install it accurately and professionally.

Tools and preparations for installation to ensure that the solar inverter works perfectly

Safety regulations and basic rules for installers

When connecting an inverter to a solar system, it is essential to comply with electrical safety standards. This is the only way to ensure that the system operates safely and for a long time. The first step in designing the system is to select the appropriate protective devices: whether it is surge protection, fuses, grounding, or touch protection.

It is important that the inverter is installed in a location that is dry, ventilated, and protected from the elements. Many inverters are sensitive to temperature, so an overly hot attic, for example, can reduce efficiency or lifespan.

If the system feeds back into the grid, the inverter must be capable of phase synchronization and have automatic disconnection in the event of a power failure (anti-islanding).

Choosing the right type and size of solar inverter

When selecting an inverter, the type of system must be taken into account: whether it is an on-grid, off-grid, or hybrid system.

The power of the panel array (string), the total DC voltage and current of the modules must be matched to the input values of the inverter: the maximum DC voltage, the MPP range of the inverter, and the output AC power are all critical factors.

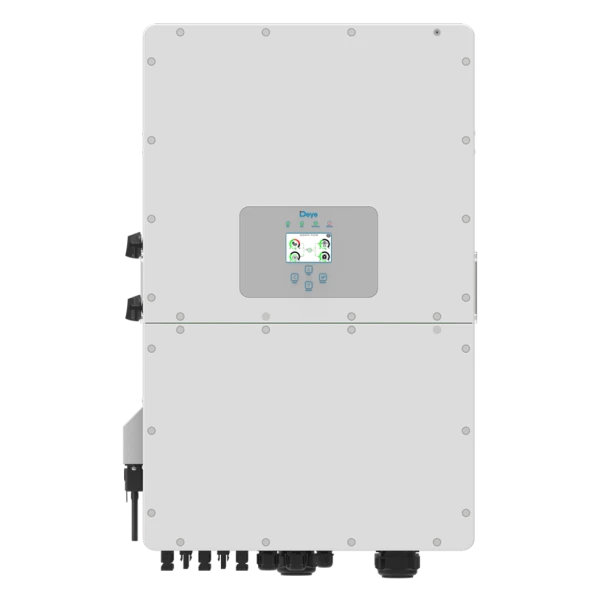

Inverter types include string inverters and hybrid inverters, each with different advantages and compromises. SolaX hybrid inverters also represent an important group of these solutions.

In addition to power and voltage matching, it is worth paying attention to efficiency (modern inverters operate at up to ~98% efficiency) and whether the inverter has built-in MPP tracking (maximum power point tracking), a monitoring system, overvoltage and overload protection, and phase symmetry.

Which is the best solar inverter?

There is no universal "best" inverter; it depends on the type of system, the number of panels, whether there is feed-in or battery storage, the power requirements, and the conditions under which the system operates. When selecting the ideal inverter , the most important thing is that the technical parameters and functions of the inverter match the characteristics of the solar system exactly.

For example, if the goal is to feed back into the grid, an on-grid inverter is a good choice, as it ensures proper phase and frequency matching, automatic disconnection in the event of a power outage, and compatibility with the utility grid.

However, if the goal is off-grid operation (or a combination of batteries and solar panels), then an inverter capable of battery charging and independent power supply is required, such as hybrid or off-grid inverters.

Finally, the reliability, efficiency, and extra features (such as monitoring, protection, MPP tracking, communication) of the inverter are also important, so it is worth choosing a quality, proven manufacturer that offers a warranty and documented parameters.

Step-by-step installation of the inverter

Cabling the solar modules and checking the polarity

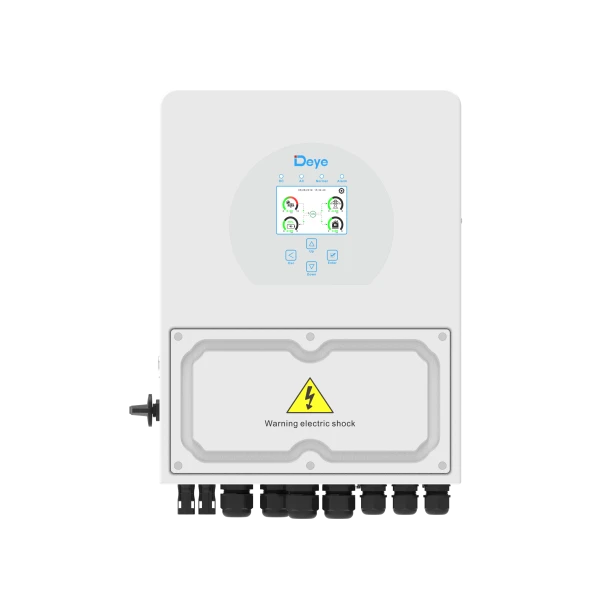

The first step in the installation process is to wire the solar modules correctly and safely. The MC4 connectors on the back of the panels are usually pre-installed, making it easy to assemble the strings, but it is still essential to check the polarity. Incorrect polarity can cause the inverter to malfunction.

After connecting the modules, the ends of the strings must be checked again to ensure that the voltage and current values are within the inverter's input range. If the string voltage exceeds the maximum DC input value specified by the manufacturer, the inverter may be damaged or fail to start.

Why is a solar inverter installation diagram useful?

A detailed inverter wiring diagram helps the installer understand the DC side connections, AC side connections, fuses, surge protection, and communication connections. Most manufacturers, such as SMA or Huawei, specifically recommend the use of installation diagrams, as they prevent faulty wiring, which is one of the most common problems with PV systems.

The advantage of a wiring diagram is that it allows you to plan the route of the cables, the position of the protective devices, the grounding point, and the connection of the AC-side distribution board before you start installation. This reduces installation time and minimizes the need for dismantling.

Connecting DC cables to the inverter

Once the power and polarity of the strings have been checked, the DC-side connection can be made. Modern inverters usually have DC inputs with surge-protected sockets and are often equipped with multiple MPP trackers. This allows panels with different orientations or different power ratings to be handled. According to SolarEdge installation guidelines, it is mandatory to check the DC disconnect switch and test it before switching on before connecting to DC.

After connection, the manufacturers recommend another polarity measurement at the input point to check that there has been no wire swap or short circuit during connection.

AC side connection to the grid

During AC side connection, the inverter transmits alternating current to the home distribution board and then to the grid. According to the EN 50549-1 standard, inverters connected to the grid must have a built-in anti-islanding function, which disconnects the inverter from the public grid in the event of a power failure.

It is important that the cross-section of the AC-side cabling corresponds to the power of the inverter, otherwise heating or voltage drops may occur, which can lead to a loss of efficiency or a fire.

Grounding, touch protection, and surge protection

One of the keys to safe operation is the installation of a proper grounding system. The IEC 60364-7-712 standard for solar installations requires that all inverters and all DC-side protection devices be connected to a common grounding point, and the use of AC/DC surge arresters is mandatory.

Surge protection is particularly important because high voltages can occur on the DC side, and a lightning strike could cause immediate failure of the inverter. In modern PV systems, it is recommended to install high-quality Type 1 and Type 2 SPD protection.

Connection of communication cables and monitoring system

The monitoring system allows real-time tracking of the PV system's performance. Most modern inverters connect to the monitoring system via Ethernet or Wi-Fi-based communication. The installation manuals of manufacturers emphasize that communication cables should be routed separately from high-voltage cables to avoid interference and data loss.

With a properly functioning monitoring system, faults, declining production values, or even cable faults can be detected quickly, which increases the long-term operational reliability of the system.

Common errors during connection and how to avoid them

When installating a solar inverter, a number of errors can occur that reduce the efficiency or operational reliability of the system, as is also the case when installing solar panels . One of the most common problems is when the voltage of the strings does not match the range allowed by the inverter, which can lead to overload or inverter shutdown. If the voltage is too low, the inverter will simply not start.

Testing and commissioning: what needs to be checked?

The final phase of installation is testing, during which it must be verified that all components of the system are operating safely and in accordance with regulations. According to PV system commissioning protocols, it is mandatory to measure DC side polarity, voltage and current values, and to verify the correct operation of protective devices.

This is followed by checking the AC side: the phase synchronization of the inverter and the automatic disconnection functions (anti-islanding) must also be checked. For grid-connected inverters, the EN 50549-1 standard specifies the mandatory commissioning tests, such as checking the frequency and voltage ranges.

Based on the manufacturer's instructions, the monitoring system must also be activated, as it indicates subsequent production data and errors. For Huawei inverters, installation also includes online registration and checking the inverter firmware.

Maintenance recommendations and long-term operational reliability

Maintenance of solar systems is typically simple, but certain components must be checked regularly to ensure that the inverter and the entire system continue to operate reliably in the long term. Manufacturers recommend performing a visual inspection at least once a year: check the condition of cables, the tightness of connections, grounding points, and the condition of surge arresters.

The monitoring system also plays an important role: if production drops or fluctuates, problems can be detected at an early stage based on the inverter's log files. Dust accumulation, aging connectors, or even a shielding fault can be indicated by the statistics.

For some hybrid inverters, the condition of the battery and its charging cycles must also be monitored, which is easily accessible from the manufacturer's software.

When is it necessary to involve a specialist for the installation?

Although installating a solar inverter is a step-by-step technical process, in certain cases it is essential to have an electrician or a specialist familiar with solar systems. This is the case, for example, when connecting a grid-fed system, which, according to the electricity supplier's regulations, can only be done by a registered specialist.

A specialist is also required if the system is high-powered, if multiple strings or fields with different orientations need to be coordinated, or if a hybrid inverter and energy storage system need to be configured.